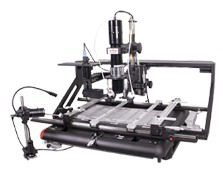

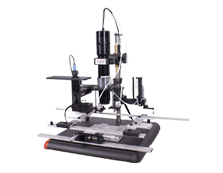

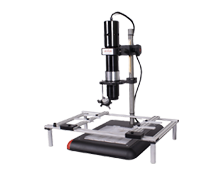

PDR designs, manufactures, and

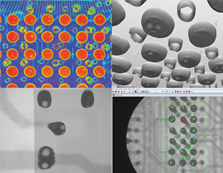

distributes IR Rework Stations, Industrial X-Ray Inspections Systems,

and IR Thermal Test equipment for the electronics component and PCB

assembly industry. Based in the UK and USA, they also have regional

technology centers in France.

PDR was formed in 1985 by Philip Gibbs, David Lowrie and Roger Gibbs and

their first pioneering IR system was launched in 1987. Over 37+ years

later, PDR is still at the forefront of SMD rework, X-Ray and Test

technologies working with many of the world's top names in

- Mobile Phone, PDA, Tablet, Laptop,

Desktop, Server repair.

- Consumer electronics, Set-top, TV, Game

Console repair.

- Aerospace, Weapons, Avionics, Automotive,

Transport electronics.

- Control and systems repair, R&D, assembly

and repair rework.

We at ESA group are a channel partner for PDR and support customers,

provide Sales and Technical Support service. There are other regional

offices plus a global network of professional sales/support partners who

have successfully supplied over 4500 systems to the world's electronics

industry since 1987.

There are many different Rework, X-Ray and Test System choices to choose

from but customers feel comfortable to choose PDR, returning in time and

time again to benefit from their advanced precision thermal engineering

Rework Systems, X-Ray imaging quality, and highly accurate and

affordable Thermal Testing Solutions.